In the world of 3D printing, polycarbonate is like that friend who shows up to the party with the best snacks—everyone wants it, but not everyone knows how to handle it. This super strong thermoplastic is making waves in the additive manufacturing scene, offering durability and versatility that can make even the toughest materials jealous. Whether it’s for creating robust prototypes or intricate designs, polycarbonate 3D printing is the secret weapon every maker needs in their toolkit.

But wait, there’s more! Not only does polycarbonate boast impressive mechanical properties, it’s also surprisingly easy to work with when you know the ropes. With the right techniques and a dash of creativity, it can transform ordinary ideas into extraordinary realities. So, if you’re ready to elevate your 3D printing game and impress your friends (and maybe even your boss), dive into the fascinating world of polycarbonate printing.

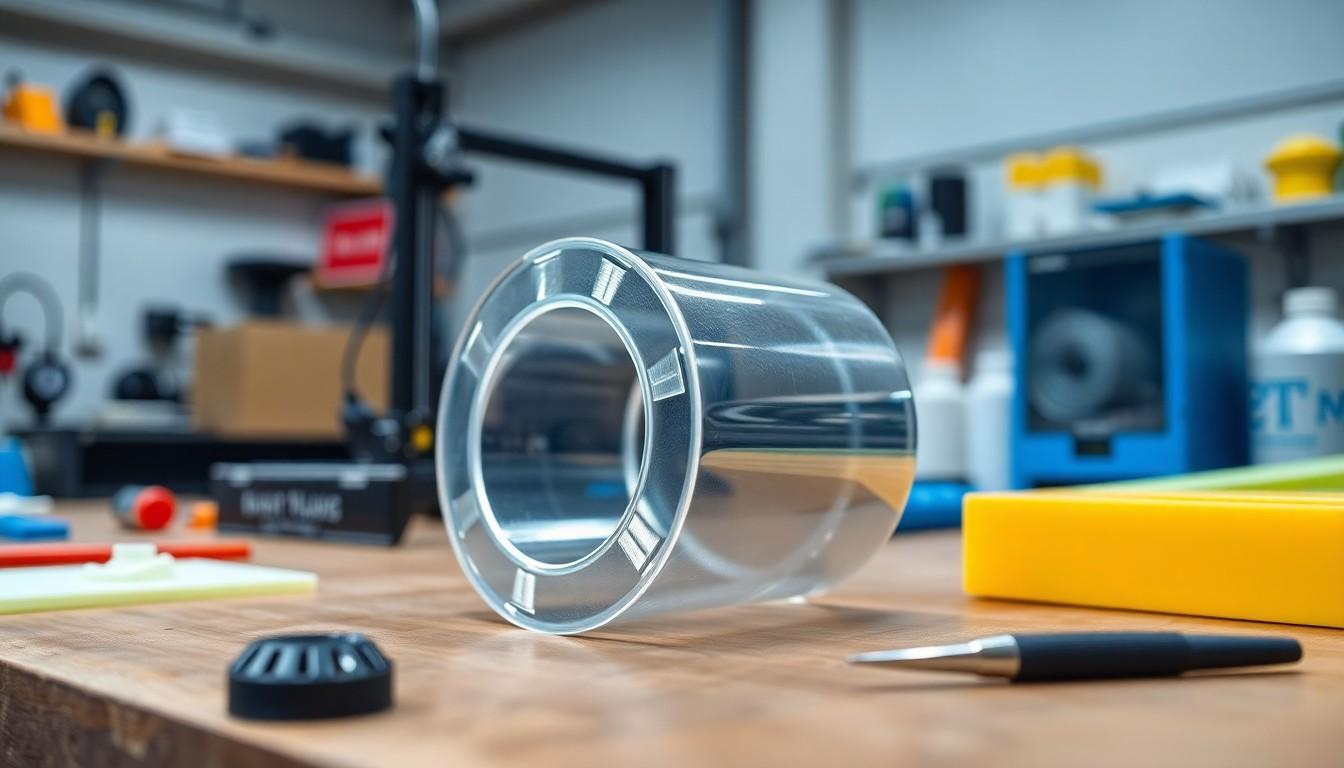

Overview Of Polycarbonate 3D Printing

Polycarbonate 3D printing offers remarkable advantages in the field of additive manufacturing. Known for its strength, polycarbonate is highly impact-resistant, making it a preferred material for durable applications. This thermoplastic can withstand high temperatures, which is essential for prints exposed to heat. Flexibility adds to polycarbonate’s appeal, allowing it to absorb stress without breaking.

Utilizing polycarbonate in 3D printing creates robust prototypes and intricate designs. Many industries, such as automotive and aerospace, benefit from its mechanical properties. Its ability to print complex geometries enhances creative possibilities for designers.

Print settings for polycarbonate need careful consideration. Maintaining a higher nozzle temperature optimizes layer adhesion. Heated print beds also help prevent warping during the cooling process.

The material’s versatility extends to post-processing options as well. Techniques such as sanding or painting improve the finished look of printed parts. While polycarbonate is manageable for experienced printers, beginners may face challenges due to its unique properties.

A strong understanding of print parameters leads to successful results. Experimentation encourages skill development and builds confidence in using polycarbonate. As the additive manufacturing world evolves, exploring polycarbonate printing promotes innovation in various projects.

Investing time in learning how to work with this material enhances overall printing capabilities. Engaging with polycarbonate expands creative avenues, allowing for impressive 3D printed creations.

Benefits Of Polycarbonate 3D Printing

Polycarbonate 3D printing offers numerous advantages, making it a popular choice among enthusiasts and professionals. Its unique properties cater to a wide range of applications.

Strength And Durability

Strength characterizes polycarbonate, making it an excellent material for 3D printing. Significant impact resistance ensures that printed parts withstand mechanical stresses. Durability plays a crucial role in producing functional prototypes. Parts printed with polycarbonate exhibit high tensile strength, which is essential for demanding environments. Additionally, polycarbonate’s resilience reduces the likelihood of breakage during handling. Projects in automotive and aerospace benefit from polycarbonate’s sturdiness, often requiring reliable components. Overall, polycarbonate stands out for creating long-lasting, high-performance products.

Heat Resistance

Heat resistance ranks among polycarbonate’s most impressive features. This material can endure temperatures reaching over 110 degrees Celsius before deforming. Applications that expose printed parts to high-heat conditions gain substantial benefits from this property. High thermal stability keeps components intact when operating in challenging environments. Engineers frequently use polycarbonate for parts in engines and other heat-generating mechanisms. Printing with polycarbonate ensures that products maintain structural integrity under intense conditions. Its heat resistance opens doors to innovative designs in various industries.

Applications Of Polycarbonate 3D Printing

Polycarbonate 3D printing has diverse applications in various industries, notably automotive and consumer products. Its remarkable properties enable functionality and creativity in design.

Automotive Industry

In the automotive industry, polycarbonate 3D printing plays a crucial role in producing lightweight, durable components. It allows designers to create parts that withstand severe mechanical stresses while remaining cost-effective. Additionally, polycarbonate’s high impact resistance makes it suitable for manufacturing safety components such as dashboards and light housings. Using advanced architectural techniques, manufacturers optimize designs for efficiency, contributing to energy savings in vehicle production. A vast range of automotive prototypes benefits from polycarbonate’s excellent thermal stability, which performs reliably under high-temperature conditions.

Consumer Products

Consumer products leverage polycarbonate in creating robust, appealing designs. Its versatility means manufacturers can fabricate items ranging from household appliances to personal electronics without compromising strength or aesthetics. Customization becomes possible through 3D printing, allowing unique designs tailored to individual preferences. The lightweight nature of polycarbonate enhances portability in various products. Moreover, enhanced resistance to heat and impact translates to longer-lasting items in everyday use. As a result, businesses can innovate more effectively, meeting consumer demands for durability and style in personal products.

Challenges In Polycarbonate 3D Printing

Polycarbonate 3D printing presents unique challenges that users should address. Printability issues often arise due to polycarbonate’s tendency to warp and delaminate during the cooling process. This material requires precise temperature control, typically above 260 degrees Celsius for the nozzle and heated beds set above 100 degrees Celsius to minimize warping. Users often need to adjust settings iteratively, as finding the optimal feed rate and layer height can be crucial for successful prints.

Cost considerations also play a significant role in the decision to use polycarbonate. Filaments made from polycarbonate tend to be more expensive than those made from PLA or ABS, often costing between $50 and $75 per kilogram. Budget constraints may limit the frequency of experiments and prototyping, influencing choices in printing materials. The additional need for specialized equipment, like an enclosed printer or upgraded extruder capable of handling high temperatures, adds to overall expenses.

Future Trends In Polycarbonate 3D Printing

Emerging trends in polycarbonate 3D printing indicate substantial growth and innovation across multiple industries. Enhanced printing technologies are streamlining the process, making polycarbonate more accessible for small and medium enterprises. Further advancements in print accuracy will improve the reliability of prototypes and final products.

Increased material formulations are on the horizon, with modifications aimed at boosting flexibility and impact resistance. Customized filaments infused with additives could enhance properties like UV resistance, expanding application possibilities in outdoor products. Future developments in multi-material printing are likely to create hybrid parts, leveraging polycarbonate’s strength alongside softer materials for improved functionality.

Sustainability concerns drive research into bio-based polycarbonate alternatives. These materials aim to minimize environmental impact while maintaining the mechanical advantages that polycarbonate is known for. Adoption of these eco-friendly options may attract environmentally conscious consumers and industries, facilitating broader market acceptance.

Integration with artificial intelligence (AI) and machine learning will optimize print settings. AI algorithms can predict ideal conditions based on historical data, reducing print failures and enhancing efficiency. Predictive maintenance tools that monitor equipment can prolong printer life and improve output quality.

Collaboration between manufacturers, researchers, and consumers is critical for pushing boundaries in polycarbonate 3D printing. Sharing data and best practices facilitates innovation, encouraging community-driven projects that showcase polycarbonate’s potential. Educational programs focusing on polycarbonate printing may cultivate a new generation of skilled practitioners capable of using its unique properties effectively.

These emerging trends position polycarbonate 3D printing as a transformative force across industries, delivering opportunities for creativity, efficiency, and sustainability. As more professionals embrace this material, its impact on manufacturing and design continues to expand exponentially.

Polycarbonate 3D printing stands out as a game-changer in the additive manufacturing landscape. Its unique combination of strength and heat resistance opens doors to innovative designs and functional prototypes. As industries like automotive and aerospace continue to evolve, the demand for durable and reliable materials will only increase.

While challenges exist, such as printability issues and higher costs, the potential rewards make polycarbonate worth exploring. With advancements in technology and materials on the horizon, the future of polycarbonate 3D printing looks bright. Embracing this material not only enhances design capabilities but also promotes sustainability and efficiency in manufacturing processes. As more individuals and businesses tap into polycarbonate’s benefits, its transformative impact on various sectors will undoubtedly grow.